Expertise

Bulk Material Handling

Metallurgical plants handle highly diverse materials whose handling remain a key source of operational difficulties.

There is no substitute for experience when it comes to designing these systems and specific knowledge of the nature of the materials is essential.

Using the best tools with the correct inputs gleaned from extensive plant exposure, our systems are designed for trouble-free operations.

Whether it be ore or concentrate, intermediate product and recycle materials, coarse and fine particles or dusts or slurries, our team has likely encountered your specific circumstances and can bring solutions to that will move the focus away from this area of the plant on an ongoing basis.

Study case

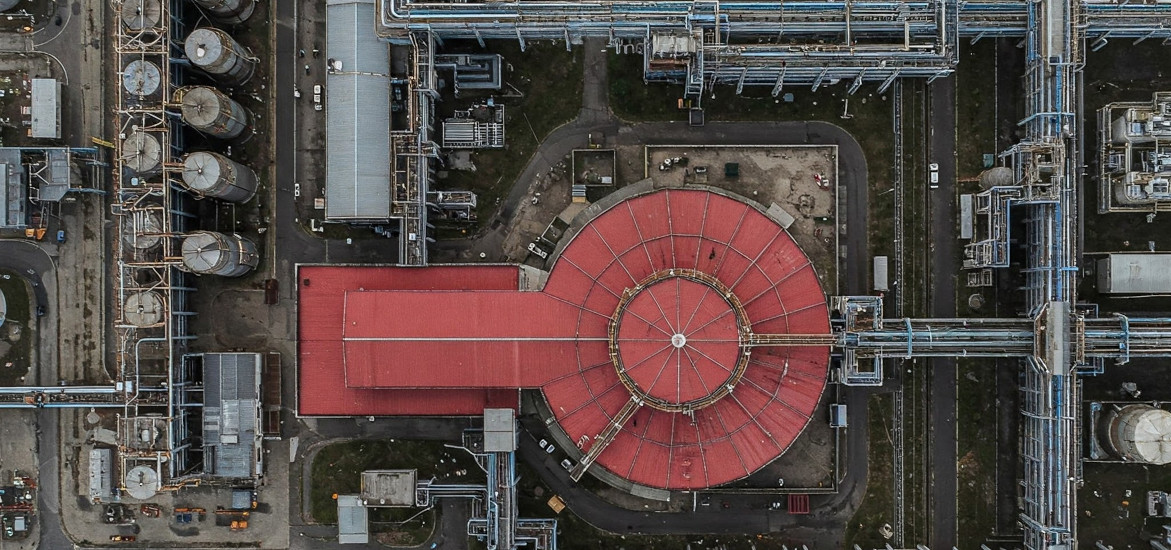

Smelter Feed and Blending Improvements

CaEng was retained to develop a study to develop options to improve a copper smelter’s recycle and reverts management strategy. Multiple options were developed as a part of the early stage study, the options were shortlisted and further defined through the pre-feasibility and feasibility stages. Following the feasibility stage, CaEng completed detail engineering for the project and supported the client through procurement, construction and commissioning. The project was staged and implemented over two plant outages.

Study case

Truck Weigh Station Detail Engineering - Zambia

CaEng was retrained to develop a new truck weigh station for an integrated copper mine and processing complex. This complex handles both oxide and sulfide deposits, processing them through either its hydrometallurgical or pyrometallurgical plants.

Our team produced the general arrangements for the weigh station, which included designs for the incoming and outgoing weigh scales, the scale house, and lighting and camera poles. CaEng also provided procurement support and the detailed design for the weigh station’s structural steel and concrete.

Study case

Smelter and Refinery Strategic Study – North America

CaEng was retained to assess the viability of accepting custom feed at the client’s smelter. All areas of the smelter and refinery were reviewed as part of the mandate and at the conclusion of the initial study, a total of 15 recommendations were presented. The customer decided to move forward with a select number of options based on prospective outcome with respect to plant and operational improvements.

CaEng has helped implement a number of solutions for debottlenecking the facility and also currently working on progressing the remaining initiatives through the study stages. A few of the implemented initiatives include, furnace cooling improvements, material handling improvements, dust and hygiene improvements, and online waste heat boiler cleaning.